Metallographic microscopes identify defects in metal surfaces, they are used to observe the corrosion process, to detect the crystal grain boundaries in metal alloys, and to study rocks and minerals, among others applications.

Failures in metals can come in many forms: fractures, cracks, inclusions, corrosion, microstructural processing issues and wear just to name a few. Getting to the root cause needs microscope instrumentation that is flexible and can provide multiple contrasting methods.

A few typical examples of FA applications in metals:

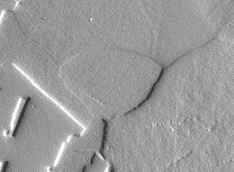

Surface corrosion in Darkfield contrast. Pit morphology can provide insight into the type of corrosion process that has taken place.

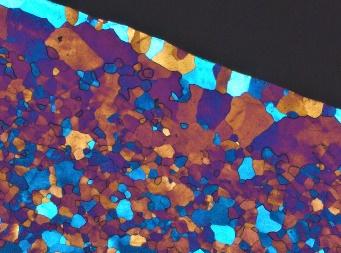

Unetched polished metallographic samples imaged in DIC (Differential Interference Contrast) can make grain structure visible and supply qualitative information into the differences in grain hardness.

Polarized Light contrast can produce striking images along with valuable understanding of the microstructure in certain types of metals.

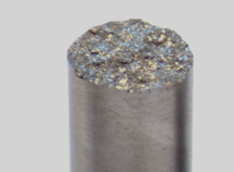

Non metallic inclusions (e.g. in steel), as seen here in Brightfield contrast, can often be the cause of fracture or corrosion.

The surface of fractures are often difficult to image all in focus due to their rough topography. Extended depth of field (Multi-Focus) can produce high resolution all-in-focus images over a large topographic range.

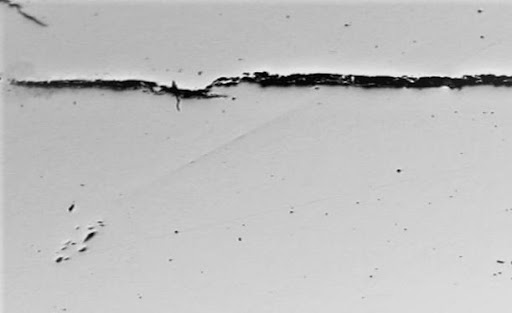

Software tiling feature can allow large image acquisition (panorama/mosaic) while maintaining high resolution which can be a valuable tool when imaging large metal cracks as seen in this example.

The PA53 MET Metallograph

The PA53 MET Metallograph is one such instrument. An Industrial grade compound microscope for Metallographic imaging. A highly modular microscope with imaging software that can be upgraded for motorized components in the future.

Reflected light Brightfield, Darkfield, DIC and Polarized Light image contrasting techniques provide high color fidelity and resolution and can bring out important image detail.

A Motic camera and software will allow you to capture and save images as well as make measurements, tile images and provide extended depth of field.

The manual objective nosepiece is encoded, enabling automatic digital scale-bar readings at every objective magnification taking the guesswork out of image size for documentation and measurement.

Copyright: Motic Scientific